Soil Health

Fertilizer Guidelines for Vegetable Crops in Arizona

Special Sections (4)

Controlled Release N Fertilizers (4.5)

A controlled-release-nitrogen fertilizer (CRN) is a granulated fertilizer that releases nitrogen (N) gradually into the soil solution. The CRN fertilizer technology is generally based on different chemical coatings that control N release rates. However, the more widely used and economically viable products are those that are based on polyurethane coating. These products, all based on similar chemistry, are manufactured under different patents and are available in various commercial names including Duration, ESN, Polyon, and Gal-Xe.

The polyurethane coating thickness of CRN fertilizer products determines the N release rate of the product. The rating of a CRN product, which defines the release rate, is labeled with the acronym “DD” followed by a number representing the number of days required for 80% release to occur in water at 20oC. For instance, a controlled-release N fertilizer labeled as DD120 would release 80% of the N in 120 days in water at 20oC. The coating thickness also affects the concentration of N in the bulk granulated product. For example, Duration with DD45 label contains 45% N, while products labeled as DD90 and DD120 contain 44% and 43% N, respectively.

Over the last three decades, the author and cooperators have conducted a series of field studies on the effects of CRN fertilizers on yield and quality of vegetable crops produced in the Yuma region, comparing them to conventional N fertilizer management practices (Figures 4-5-1 and 4-5-2). These studies have identified scenarios that may result in five distinct outcomes: (i) a reduction in yield, (ii) no change in yield, (iii) a reduction in N fertilizer required for optimal yield, (iv) improved yield and quality, and (v) some combination of reduced N fertilizer requirement for maximum yield and improved yield and quality. Each of these potential outcomes will be discussed next.

(i) Scenarios in which the use of CRN fertilizer leads to yield reduction:

Poor plant stand, and subsequent reduction in yield, can occur if a CRN fertilizer is used under conditions of elevated soil temperatures. In this scenario, N will be released at a more rapid rate into the soil solution to an extent that it may cause osmotic stress and/or ammonia toxicity to emerging seedlings. These observations were made for mid to late September plantings when CRN products rated as DD90 or quicker release rates are used.

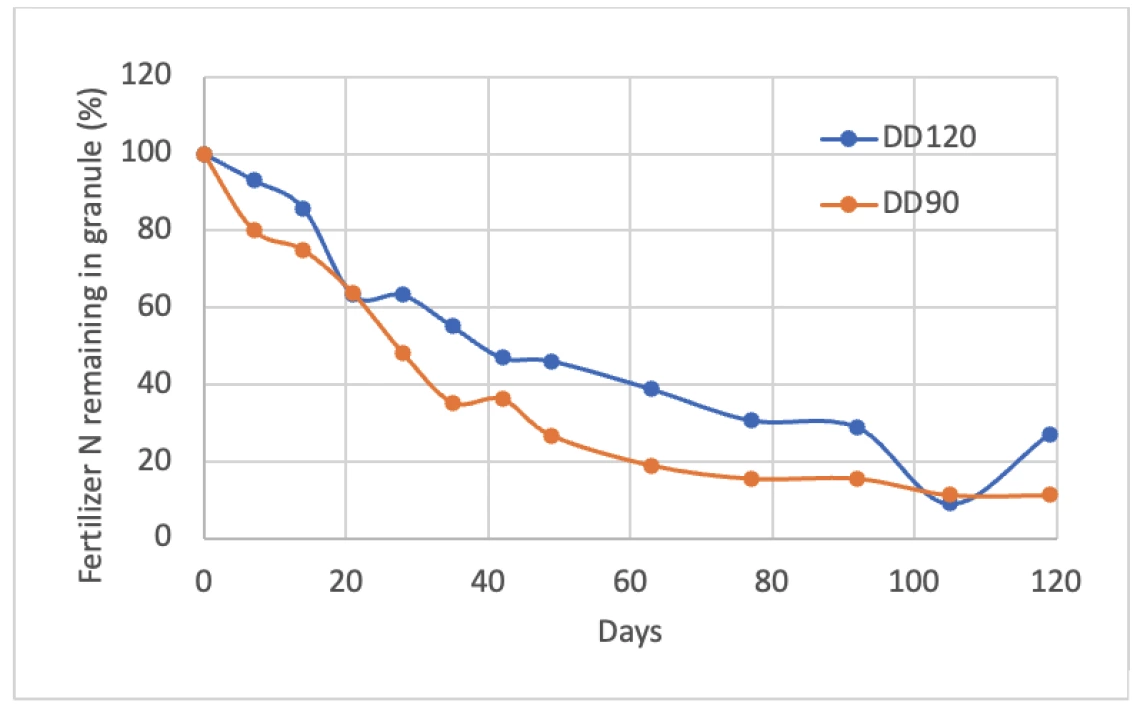

Reduction in yield was also observed when there was a mismatch between product release rates and crop demand. The author and cooperators conducted N release rate field studies to develop models for predicting the correct matching of CRN products with anticipated crop N demand. In general, the results show that optimal application time window for CRN fertilizer products during the vegetable growing season varies with the crop and product rating combination. The time variation of residual N levels of CRN products rated as DD90 and DD120 obtained in a study conducted over a period of about four months, starting from September 16, are depicted in Figure 4-5-3. It can be observed that the slope of each curve in Figure 4-5-3 represents the release rate of the respective CRN products. Considering a base temperature of 5oC, optimal time window for product application for different crops was determined by matching predicted N release rates with crop growth periods. Results show that for lettuce, broccoli, and cauliflower plantings, products rated as DD120 to DD150 should be applied prior to October 10 to prevent potential crop damage due to rapid N release. By comparison, for the same crops, DD90 should be applied after October 10 to ensure that the N release rates keep pace with crop demand. For short season crops like baby spinach and baby lettuce, DD90 should be applied prior to October 10, while a suitable time for the application of DD45 to these crops is after October 10.

(ii) A scenario in which the use of a CRN fertilizer produces a comparable response to that of conventional N management practices:

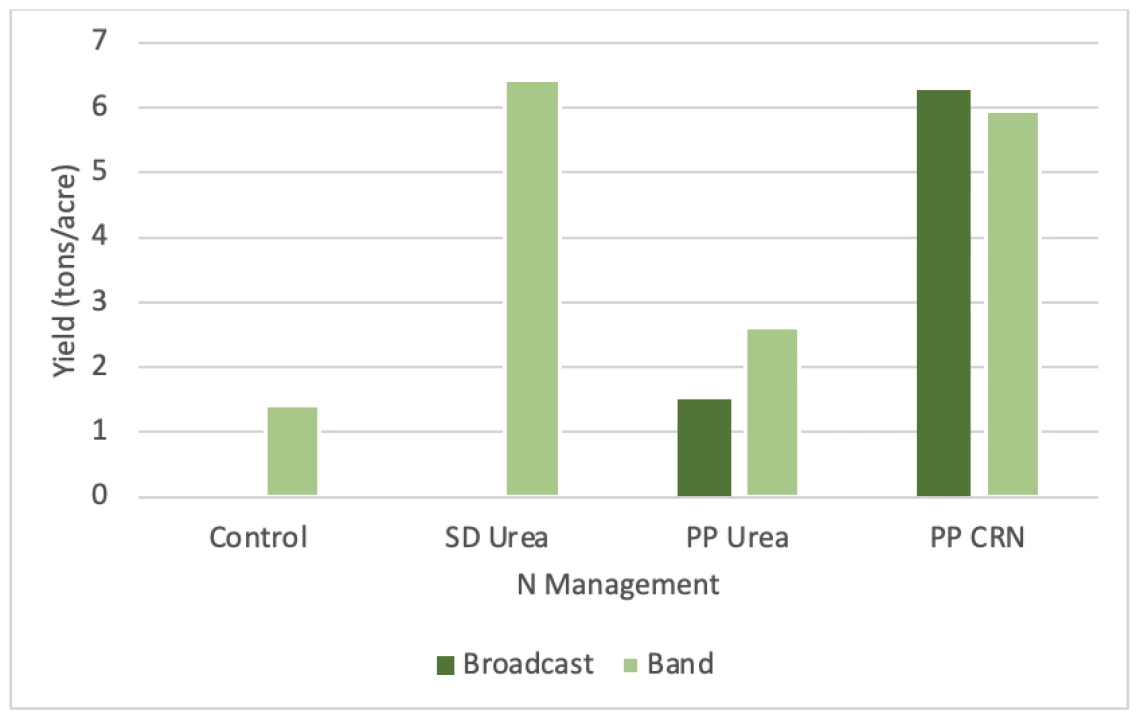

Such a scenario occurs when the timing of an application with conventional management is optimal, resulting in minimal N leaching and denitrification losses. This scenario can at times be observed where crops are grown on heavier soils under sound irrigation management. As can be noted from Figure 4-5-4, a CRN fertilizer applied to a broccoli crop grown on sandy loam soil produced yield response only matched by split side-dress application and was superior to the other methods considered. Although a CRN program has the advantage of reduced tractor operational cost compared to side dressing or top dressing of N fertilizers, this benefit is often offset by the higher cost of CRN fertilizers. As noted in Section 2-1, the movement of N fertilizer through the soil system is mainly affected by advective transport mechanism. Consequently, there is no difference between pre-plant band or broadcast applications of N fertilizers with regard to crop availability as shown in Figure 4-5-4.

(iii, iv, and v) The third, fourth, and fifth CRN fertilizer management scenarios:

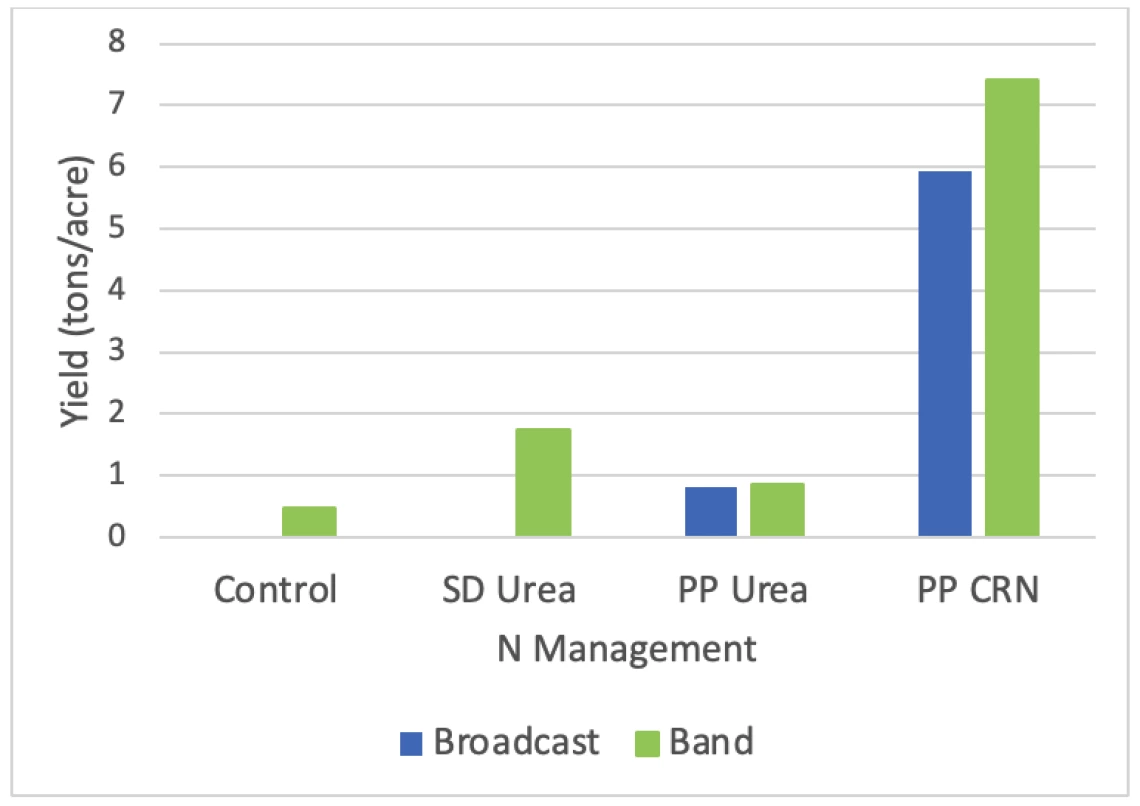

Each of these scenarios produce positive outcomes. Observed benefits of CRN management under these scenarios include reduced N fertilizer application rates for optimal yield compared to conventional N fertilizer management options (Figure 4-5-5, Scenario iii), improved crop yield and quality relative to conventional N fertilizer management practices (Figure 4-5-6, Scenario iv), and some combination of these beneficial outcomes (Scenario v).

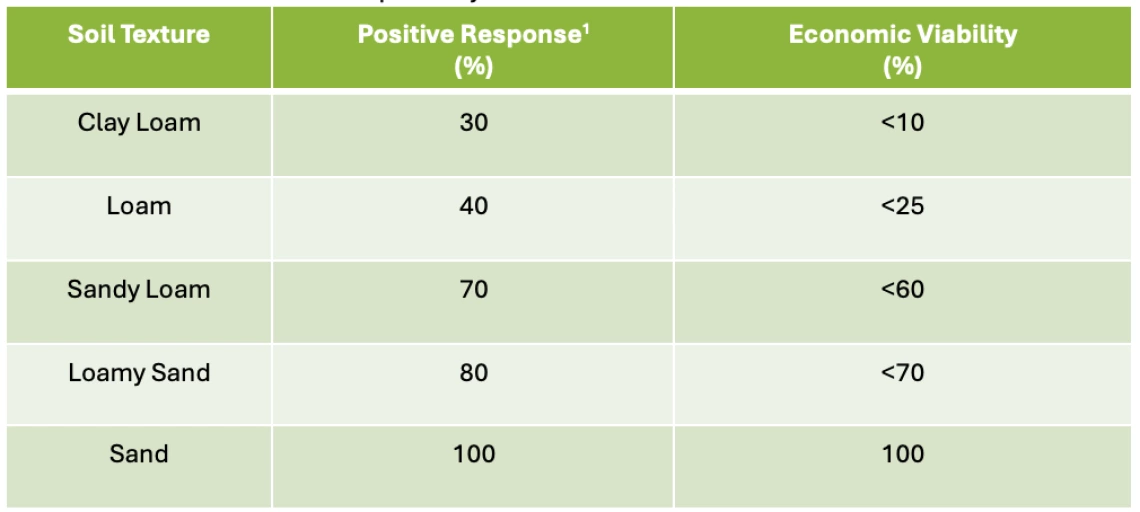

Overall, results of the studies summarized in Table 4-5-1 show that the likelihood of a positive crop response from a CRN program, measured in terms of yield or economic benefit, increases as soil texture becomes increasingly coarse. However, yield increases or quantified fertilizer savings do not necessarily translate into increased economic benefit primarily because CRN fertilizer products are more expensive than traditional water soluble N fertilizers.

Sometimes N management programs with mixed CRN and soluble N sources are the most economical when not the most effective. Yield response of lettuce crop, grown on loamy sand soil, in which N requirements are applied through some mix of CRN and sidedress method are compared in Figure 4-5-7 with scenarios having different combinations of urea applied in split side-dress applications and CRN applied and pre-plant broadcast. Evidently, the options in which N requirements are applied through some combination of CRN and side-dress of urea led to increased yield relative to those of the alternative practices.

Some growers in the Yuma area have reported benefits from using CRN fertilizers in pre-plant N application. Under such scenarios, the CRN can be blended with pre-plant monoammonium phosphate (MAP), which is primarily used as a phosphorous source. However, additional follow up studies are needed to develop conclusive fertilizer management recommendations for CRN products that are used to apply only some fraction of the crop N requirements.

In fields that are irrigated with sprinkler or drip systems, more frequent application of soluble N fertilizers through fertigation is feasible. Thus, the use of CRN fertilizers may not offer an advantage over well-managed sprinkler/drip fertigation systems.

Figure 4-5-1

Controlled release fertilizer experiment conducted at the Yuma Agricultural Center with iceberg lettuce, which was part of a study conducted over a period of 30 years on various vegetable crops in Arizona including lettuce, broccoli, cauliflower, spinach, watermelons, potato, and tomato.

Figure 4-5-2

Controlled release fertilizer experiment with spinach crop grown in a grower-cooperator field in the Lower Colorado River Region.

Figure 4-5-3

Release rates of two Controlled Release Nitrogen (CRN) products in a field over a period of about four months (spanning September 16 to January 10). These studies were conducted with CRN products in buried mesh bags.

Figure 4-5-4

Response of furrow-irrigated broccoli to N management on sandy loam soil

Note: Pre-plant (PP) CRN was superior to soluble urea applied preplant (PP) but not to split side-dress (SD) application of urea. Control is no N fertilizer.

Figure 4-5-5

Yield response of furrow irrigated lettuce to N management on clay loam soil. Maximum yield was obtained at an application rate of 111 lbs N/acre for Controlled Release Nitrogen (CRN) management compared to 146 lbs N/acre for split sidedress of ammonium nitrate (AN 20) application, and 191 lbs N/acre for all pre-plant AN20.

Figure 4-5-6

Response of furrow irrigated cauliflower to N management on sandy loam soil. Controlled Release Nitrogen (CRN) management at a rate of 241 lbs N/acre was superior to application of pre-plant (PP) urea and split-sidedress (SD) at a rate of 285 lbs N/acre. Control is no N fertilizer.

Table 4-5-1

A summary of responses to CRN management over multiple experiments conducted over the past 30 years

1A positive response includes yield increase or N fertilizer savings at optimal production.

Figure 4-5-7

Response of furrow irrigated lettuce to urea applied pre-plant (PP), split-sidedress (SD) urea combinations of Controlled Release Nitrogen (CRN) and sidedress (SD) urea. Control is no N fertilizer.